Guide to Engaging China Injection Molding Suppliers

So, the big meeting just wrapped up. your new project has the green light, the schedule is tight, and funding is, to put it mildly, limited. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

You nod, of course. It makes sense on paper. The cost savings can be huge. However, your brain is racing with concerns. You’ve heard the stories, haven’t you? Quality failures, endless communication gaps, shipments arriving months late and nothing like the prototype. It feels like walking a thin line between big savings and total project failure.

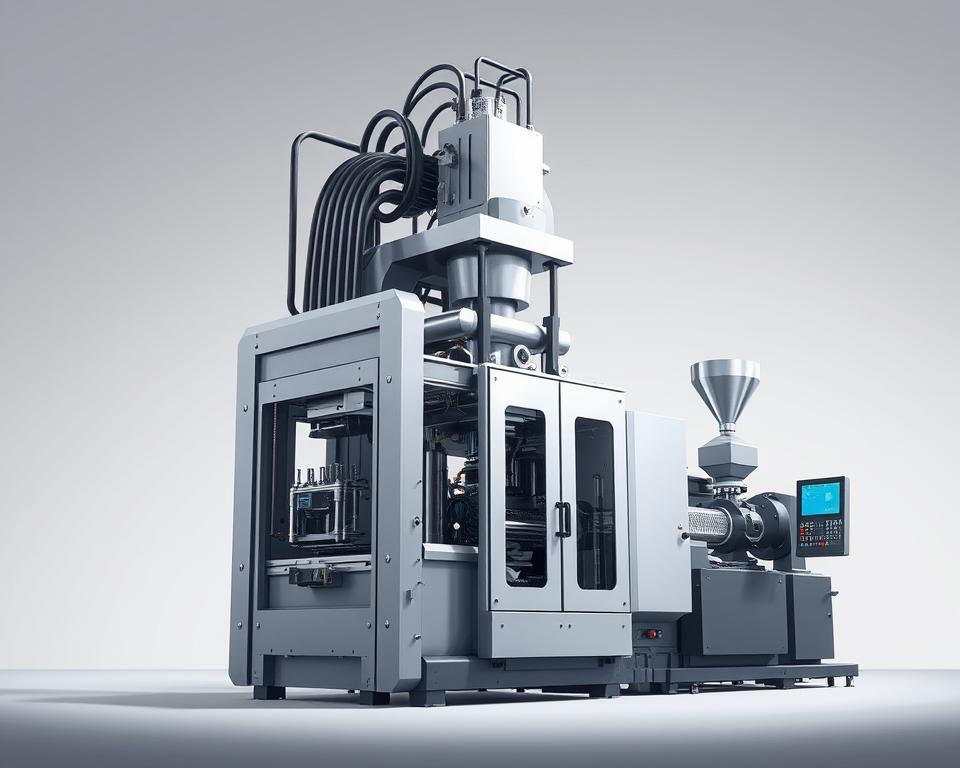

But here’s the catch. Sourcing plastic mold company doesn’t have to be a gamble. It’s simply another project with clear steps. And as with any project, success depends on your methodology. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Disregard those scary tales. Let’s go through a step-by-step guide to succeed.

First Things First: Your Homework

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You can’t expect a factory on the other side of the world to read your mind. Sending a vague request is like asking a builder to quote you for “a house.” The replies will range from absurdly low to exorbitant, none of which help.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. This package is your project’s foundation.

What belongs in your RFQ?

Start with your 3D design files. They cannot be skipped. Use standard formats such as STEP or IGS to ensure compatibility. This is the master blueprint for your part’s geometry.

However, 3D alone won’t cut it. You also need detailed 2D drawings. This details critical info missing from the 3D file. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Next up, material. Don’t just say “Plastic.” Don’t even just say “ABS.” Get precise. Specify SABIC Cycolac MG38 in black, if that’s the resin you need. What’s the reason? Because there are thousands of plastic variations. Defining the exact material guarantees the performance and appearance you designed with what is plastic mold.

They can offer alternatives, but you must provide the initial spec.

Don’t forget the commercial info. What’s your forecasted annual volume (EAU)? They need clarity: is it 1,000 total shots or a million units per annum? Tool style, cavity count, and unit cost are volume-driven.

Finding the Right Supplier

Okay, your RFQ package is a work of art. now, who do you send it to? Online sourcing is global but crowded. It’s easy to find a supplier; it’s hard to find a good one.

Begin on popular marketplaces such as Alibaba or Made-in-China. They offer breadth but not depth. But think of them as a starting point, not the finish line. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

Still, you must dig deeper. Perhaps hire a local sourcing specialist. Yes, they take a cut. But a reputable agent brings pre-screened factories. They are your person on the ground, navigating the language and cultural barriers. On your first run, this is like insurance. Think of it as insurance for your project timeline.

Another tactic: trade exhibitions. With budget permitting, Chinaplas or similar shows are invaluable. Meeting onsite is unbeatable. Inspect prototypes, interview engineers, and sense their capabilities. Also, leverage the tried-and-true referral network. Ask other project managers in your network. Peer endorsements carry huge weight.

Separating Real Suppliers from Pretenders

After firing off that RFQ to a broad pool, estimates roll in. You’ll see ridiculously low offers and steep quotes. Your task is to filter them down to 2–3 credible finalists.

How do you do that? It blends technical checks with intuition.

First, look at their communication. Are their replies prompt and clear? Do they communicate effectively in English? The true litmus: are they raising smart queries? A great supplier will review your RFQ and come back with thoughts. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” This is a massive green flag. You know they know their stuff. A supplier who just says “No problem” to everything is a walking red flag.

Next, dig into their technical capabilities. Request their machine list. Seek samples or case studies of comparable projects. A small-gear shop won’t cut it for a big housing.

Finally, inspect the factory. This is not optional. As you vet staff, you must vet suppliers. Either visit in person or engage a local audit service. They perform a one-day factory inspection. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. That small investment can save you thousands.

From Digital File to Physical Part

You’ve selected your partner. you’ll agree on terms, typically 50% upfront for tooling and 50% upon first-sample approval. Now the real fun begins.

Your supplier’s first deliverable is a DFM analysis. DFM stands for Design for Manufacturability. It’s the engineering critique for moldability. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. Comprehensive DFM equals a top-tier supplier. It becomes a joint effort. Together, you tweak the design for best manufacturability.

Once the DFM is approved, they’ll start cutting steel to make your injection mold tool. In a few weeks, you’ll see “T1 samples are on the way.” These are the very first parts off the new tool. It’s your first real test.

T1 parts usually require adjustments. This is normal! There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You’ll provide detailed feedback, they’ll make small adjustments (or “tweaks”) to the tool, and then they’ll send you T2 plastic mold samples. This process might take a couple of rounds. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

At last, you get the perfect shot. Dimensions, finish, and performance all check out. This is your golden sample. You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Crossing the Finish Line

Landing the golden sample is huge, yet the project continues. Next up: mass manufacturing. How do you ensure that the 10,000th part is just as good as the golden sample?

Put a strong QC process in place. Typically, this means a pre-shipment audit. Bring in an external QC firm. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. They provide a photo-filled inspection report. Only after you approve this report do you authorize the shipment and send the final payment. This step saves you from a container of rejects.

Don’t forget shipping details. Know your shipping terms. Are you on FOB terms, where they load and you take over? Or is it EXW (Ex Works), where you are responsible for picking it up from their factory door? These details have a big impact on your final landed cost.

Sourcing from China is a marathon, not a sprint. It’s about building a relationship with your supplier. View them as allies, not vendors. Transparent dialogue, respect, and process discipline win. No question, it’s demanding. However, armed with this guide, you’ll secure savings and keep high standards intact. You’re ready.